Black Annealed Tie Wire

- Overview

- Related Products

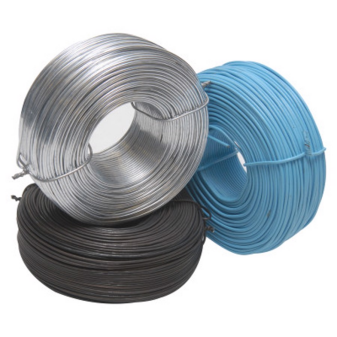

Black Annealed Tie Wire

| name | Black Annealed Tie Wire |

| Material | low carbon wire |

| Size | Wire Diameter:0.8mm (20 AWG) to 2.5mm (12 AWG) |

| Application | weaving wire mesh,baling or construction. |

| Characteristic |

softer than ordinary black wire Stronger flexibility,Uniformity of softness,chromaticity is the same. |

| Package |

Inside with plastic fim,outside weaving bag. inside with plastic film,outside hessian cloth. |

Product Overview

Black Annealed Tie Wire (also known as soft annealed binding wire or black iron wire) is a low-carbon steel wire that has undergone an annealing process to increase flexibility and reduce brittleness. It features a dark oxide surface (from annealing) and is commonly used for bundling, baling, and light construction applications due to its ease of handling and knotting.

1.Key Specifications

Material:Low-carbon steel (Q195, SAE 1008-1010)

Wire Diameter:0.8mm (20 AWG) to 2.5mm (12 AWG)

Tensile Strength :300–500 N/mm² (soft annealed for flexibility)

Surface : Smooth, dark oxide layer (uncoated)

Elongation: ≥15% (excellent ductility)

Standards :ASTM A641, ISO 8458-1, EN 10218-2

2.Manufacturing Process

Wire Drawing: Cold-drawn to precise diameters.

Annealing: Heated to 650–750°C in a controlled atmosphere, then slowly cooled to soften the wire.

Surface Oxidation: Natural dark oxide layer forms during cooling (no additional coating).

Spooling: Wound onto coils (typically 5kg–50kg) or spools (100kg–500kg).

3. Applications

Construction: Tying rebar, securing scaffolding, bundling pipes.

Agriculture: Baling hay, trellising plants, fencing repairs.

Packaging: Binding cardboard, securing pallet loads.

DIY/Home Use: Crafts, temporary fixes, gardening.

4. Competitive Advantages

✔ Superior Flexibility: Easy to twist and knot by hand (unlike hard-drawn wire).

✔ Rust-Resistant Oxide Layer: Mild corrosion protection for indoor/short-term outdoor use.

✔ Cost-Effective: 20–30% cheaper than galvanized or PVC-coated wires.

✔ Wide Compatibility: Works with manual tools or automatic baling machines.

5. Quality Assurance

Bend Test: Wrapped around a mandrel (2x diameter) without cracking.

Dimensional Tolerance: ±0.02mm for consistent diameter.

Batch Certification: Mill test reports (MTRs) available.