Hot Dipped Galvanized Wire

- Overview

- Related Products

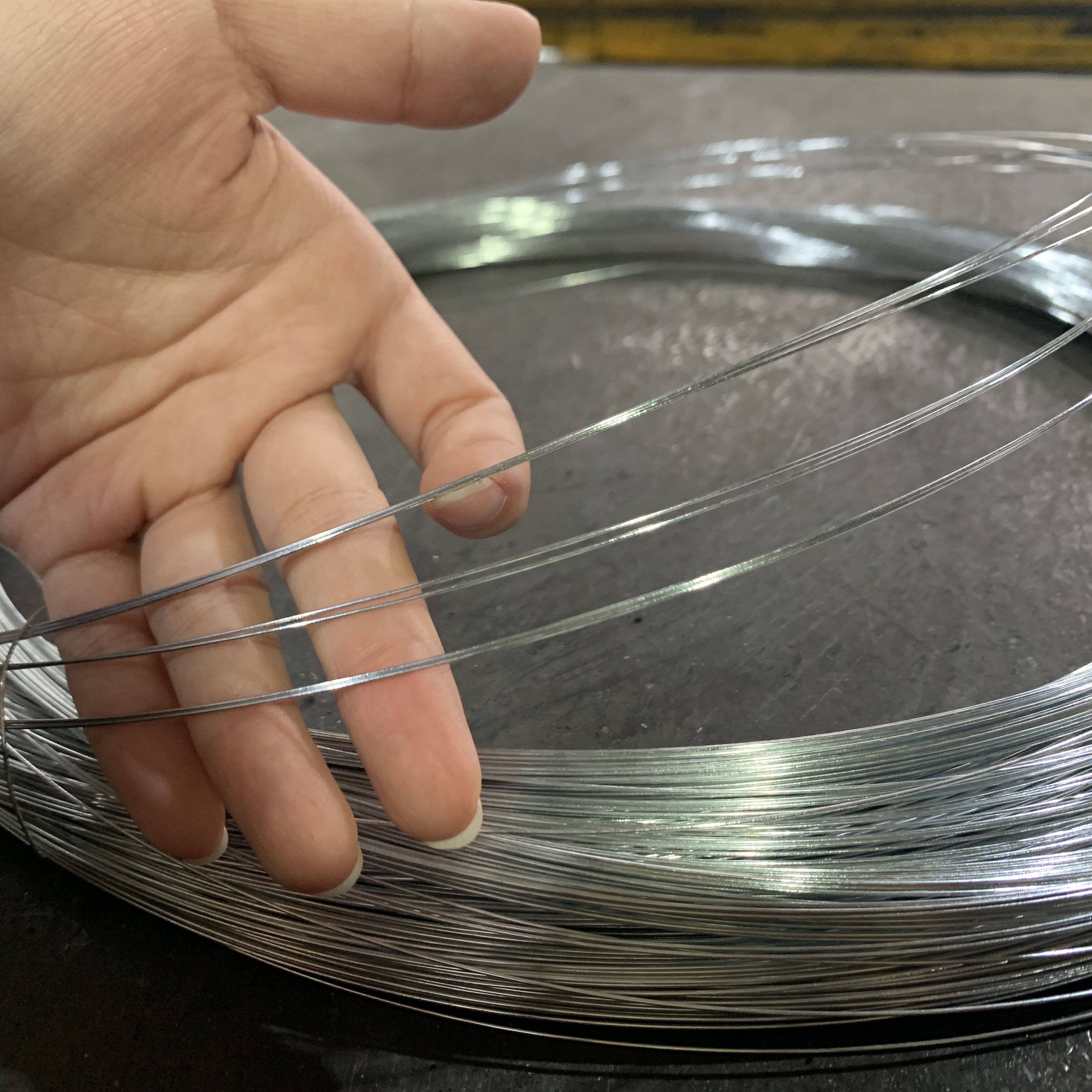

Hot Dipped Galvanized Wire

| name | Hot Dipped Galvanized Wire |

Material |

high quality Q195 low-carbon steel |

Diameter range |

BWC6-BWG26 |

Zinc coated |

40-350g/m² |

Tensile strength |

350-550N/mm² |

Elongation |

15% |

| Coil weight | 1kg-1000kg or as requirements |

Product Overview

Hot-Dipped Galvanized Wire (HDG Wire) is a corrosion-resistant steel wire manufactured by immersing cleaned steel wire in molten zinc (typically at 450°C/842°F), forming a metal lurgically bonded zinc-iron alloy coating. This process provides superior rust protection compared to electro-galvanizing, making it ideal for harsh environments.

1.Key Specifications

Base Material:Low-carbon steel (Q195, Q235, AISI 1008-1018)

Wire Diameter:0.7mm–6.0mm (custom up to 10mm)

Zinc Coating: Class 1 (Z100): 60–80g/m² (indoor use)

Class 3 (Z200): 150–200g/m² (outdoor standard)

Class 4 (Z275): 250–350g/m² (marine/industrial)

Tensile Strength:350–550 N/mm² (can be soft/medium/hard drawn)

Standards:ASTM A641 (US), ISO 7989-2 (EU), JIS G3532 (JP)

2. Manufacturing Process

Wire Drawing: Cold-drawn to precise diameters with controlled elongation.

Acid Cleaning: Removes mill scale/rust (HCl or H₂SO₄ bath).

Fluxing: Ammonium chloride/zinc chloride pretreatment.

Hot-Dip Galvanizing: Immersion in 99.9% zinc at 450°C.

Passivation: Chromate or water quenching to prevent white rust.

3. Applications

Construction: Binding rebar, suspension cables, mesh weaving.

Agriculture: Vineyard trellises, livestock fencing, baling twine.

Industrial: Safety grilles, conveyor belts, spring manufacturing.

Marine: Dock rigging, fish cages (with Class 4 coating).

4. Quality Assurance

Coating Adhesion Test: Wrapped 6x around mandrel (no flaking).

Salt Spray Resistance: 500–1,000 hours (ASTM B117).

Zinc Thickness Measurement: Magnetic gauge (min. 50µm for Z200).